Robotic Metal 3D Printing with Opus Mach

Discovering an Opportunity with the Ion Fusion Formation Patent

For my capstone project at Carnegie Mellon University, I helped commercialize a patent called Ion Fusion Formation (IFF) for Opus Mach. This technology was acquired from Honeywell and is valuable because it uses a plasma beam for 3D printing, instead of a laser beam, this means 3D printing does not need a chamber and there is no limit to a print's size. IFF also works with metal as opposed to plastic, which means it could be used for industries such as automotive, military, and transportation. Our task was to research this technology, find an appropriate market to target, and develop a plan for entering that market. In the end we created a business, service, and product plan along with an execution timeline.

My Role

With a team of two engineers and one MBA, I led the research effort, designed an app interface for the 3D printer, created a mockup of the 3D printer, created a service interaction model, and edited our product vision films. The two engineers coded and prototyped the robotic printer using Arduino, a 3Doodler, and a robotic arm. The MBA created the business strategy and execution timeline.

discovery

Finding Problems

We started by identifying problem opportunity gaps for metal additive manufacturing and Ion Fusion Formation (IFF). We interviewed various stakeholders related to additive manufacturing and assimilated a variety of research resources to help brainstorm opportunities.

Visiting the Opus Mach Warehouse

Gaps as Opportunities

We looked at gaps in the market pertaining to 3D metal printing, these gaps pointed to opportunities we could build upon. The following is a sample of over 100 gaps we discovered:

- Lack of education for businesses adopting new 3D printing technology

- Lack of highly detailed one‐off prototyping at affordable price

- Lack of compact 3D metal printers for consumer use

- Lack of ability to build large‐scale prototypes because of 3D printer protective shield

- Difficult for non‐engineers to use additive manufacturing due to learning curve

- Prohibitive for small-to-medium-sized businesses to own metal 3D printers

With further refinement, we articulated an opportunity that would be relevant for Opus Mach:

Increase accessibility to metal additive manufacturing for businesses in the Detroit area, while developing a usable Ion Fusion Formation (IFF) printer.

Defining the Opportunity

We translated this information and insights into visualizing a solution. We first refined various opportunities into three key segments: building a consultative and collaborative service model, designing an IFF printer and building a prototype, and finally exploring partnerships to further expand the business model. We refined these using a decision matrix to a printer and a service design.

Below is a promotional video we created to excite our sponsor about the opportunity we were defining.

Participatory Design

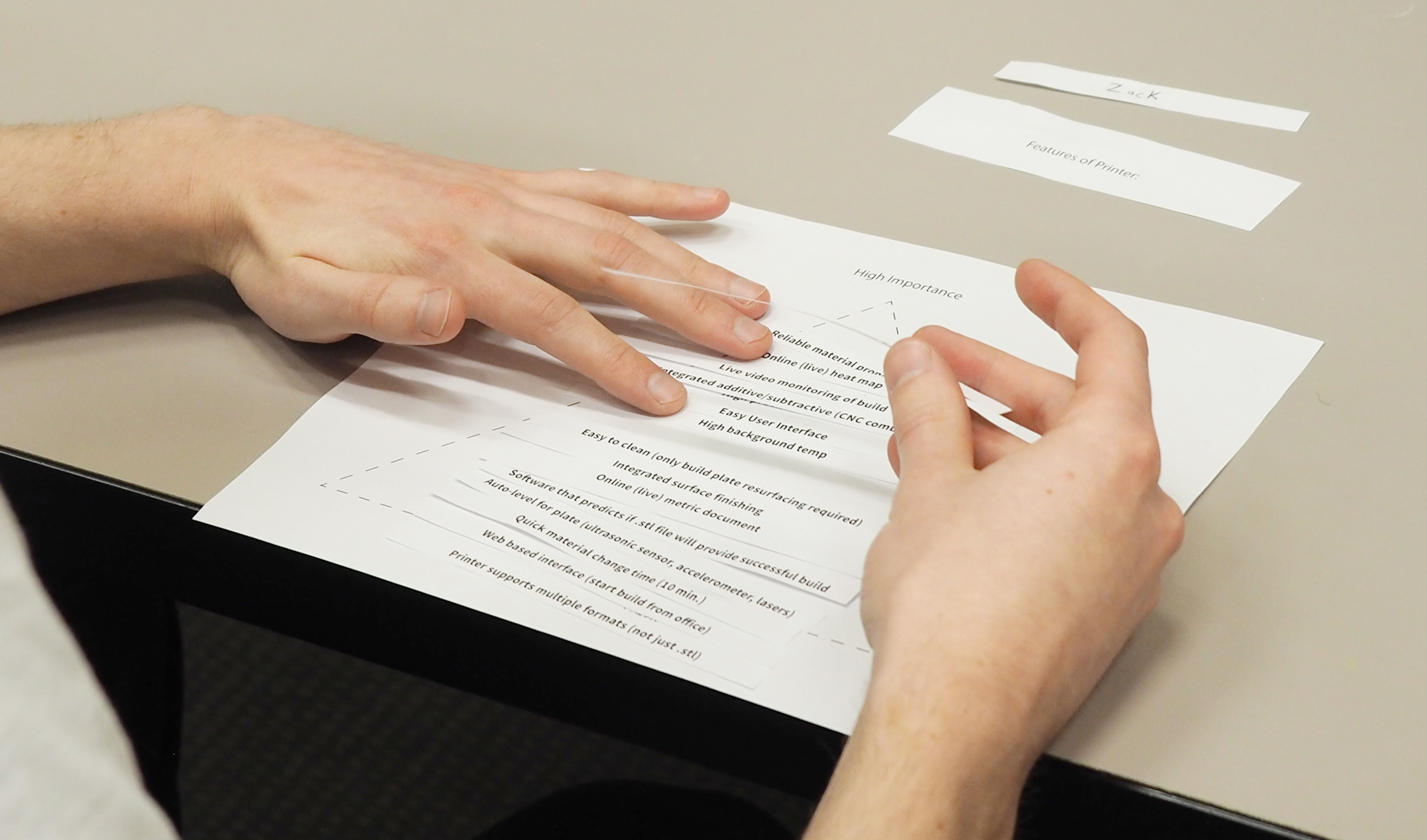

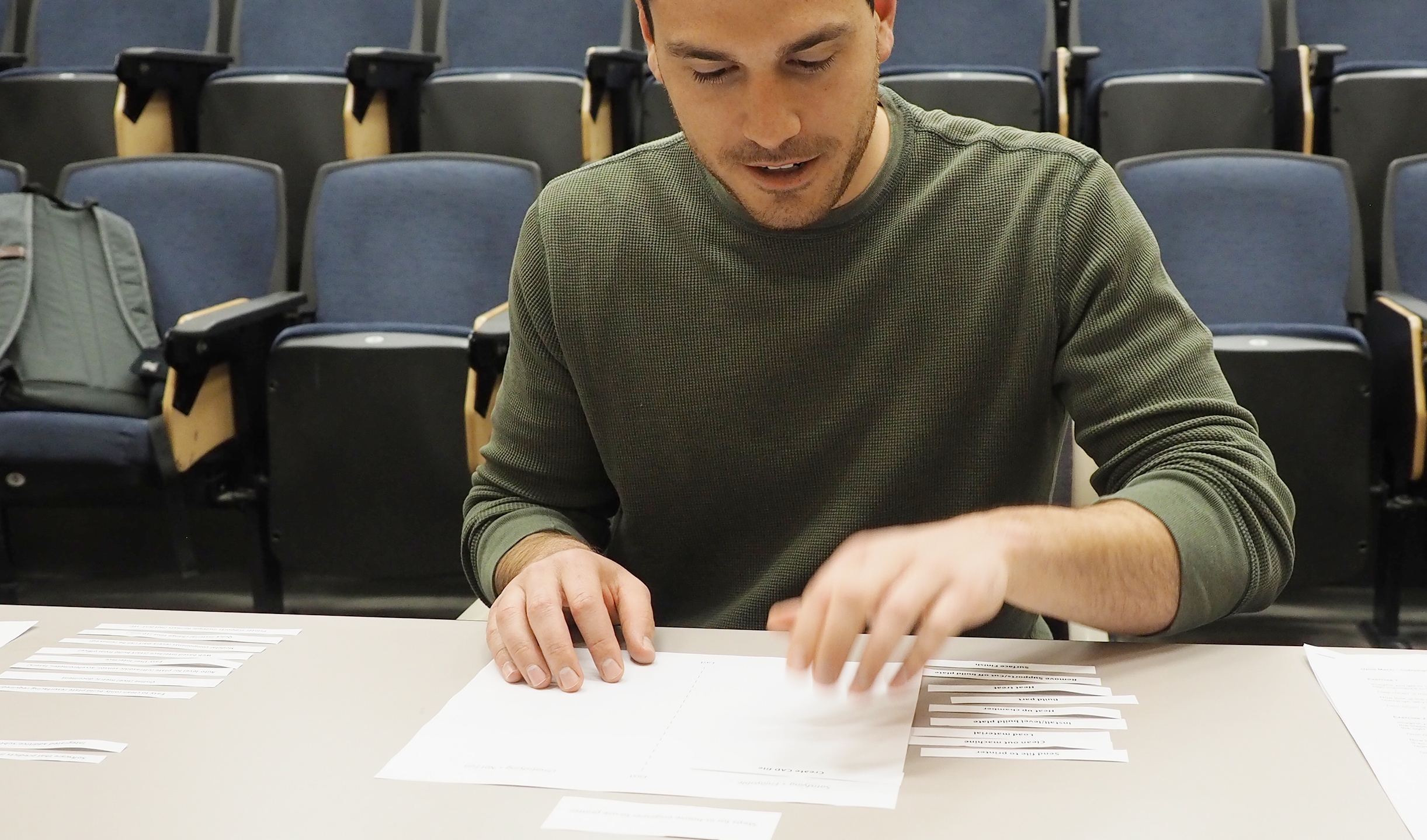

We conducted a co-design exercise with engineers and additive manufacturing machine operators to identify which printer features they valued the most, their satisfaction with each process, and what pain-points we could solve. For the service design, we interviewed prospective customers and developed an understanding of the gaps in their service experience with external vendors.

Analysis

After assessing the pain-points and successes engineers experienced during the build process we used a quad chart analysis to determine which features were both highly desirable for engineers and which were relatively easy for Opus Mach to accomplish. This analysis helped us develop a plan of execution.

creation

Solutions

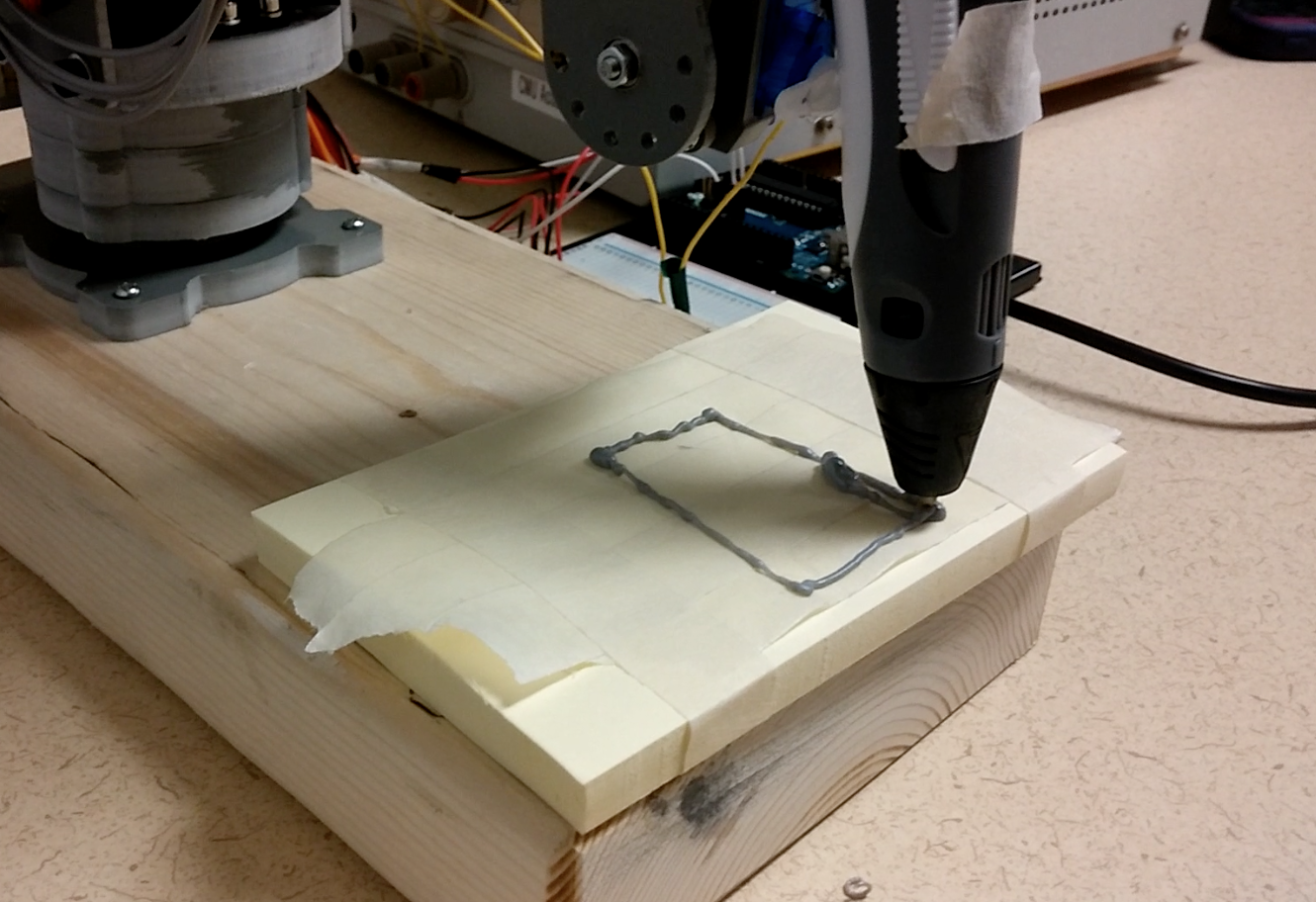

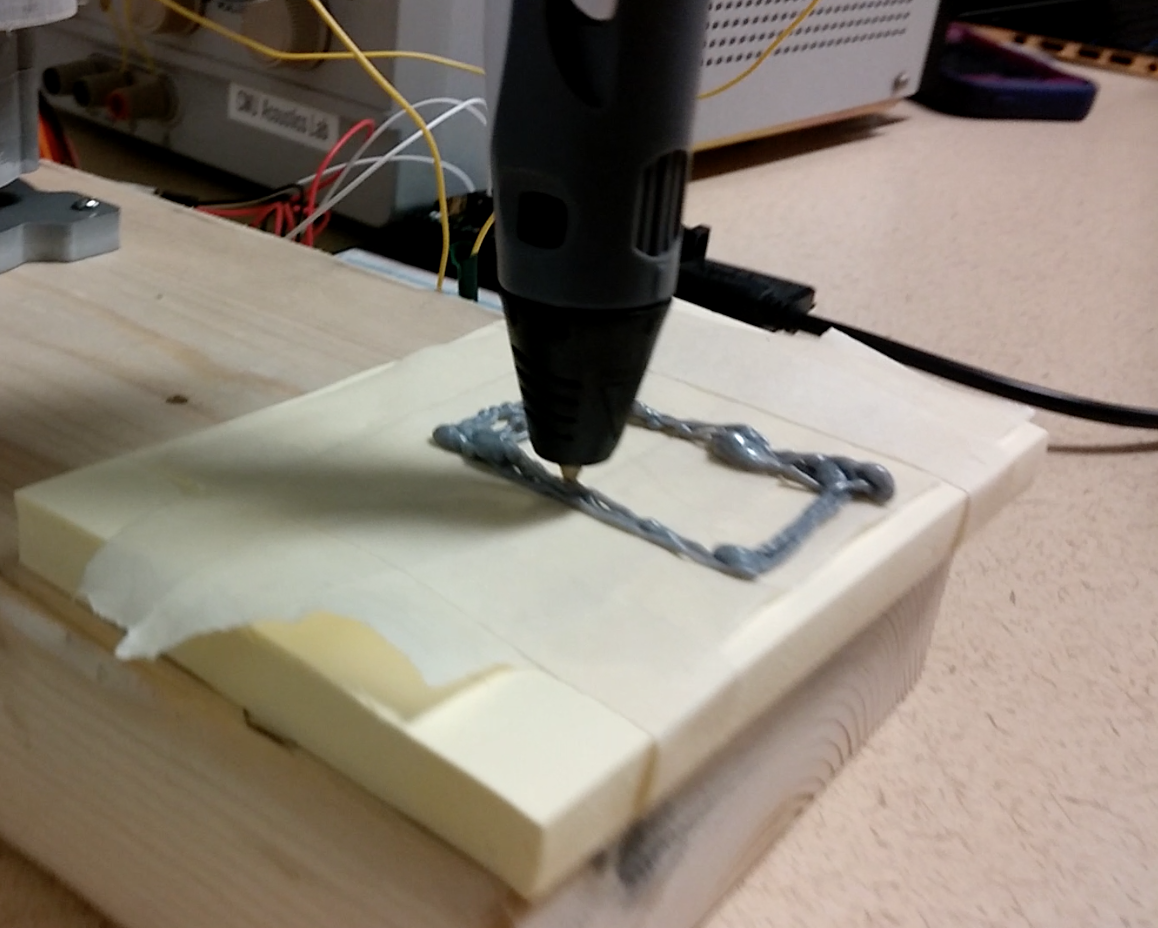

We iterated upon various ideas for the printer that met the requirements our analysis provided, and finalized on one concept based on robotic arms. We further developed a prototype to prove the concept. For the service, we identified the current service model and pain-points in the service design. Using our insights from conversations with customers, we articulated two recommendations to streamline the process for the IFF printer.

Prototype

Although the building of a full-scale printer was beyond the scope of this class, we desired to learn more about what needed to be considered for the eventual building of the printer. Incorporating the major design ideas for the printer, a small-scale prototype was built to gain more in-depth information about the challenges that can be expected from the building process. This prototype included a 6-axis robotic arm with a reach of about 11 inches. A plastic extruder and heater was fixed to the end of the arm, and an Arduino microcontroller was used to govern the movement of the arm. Code was written for the arm to sweep layers of plastic back and forth, raising slightly each layer to create 3D shapes.

Service and Business Model

Finally, we tied both the service and the IFF printer using a business model canvas framework. By identifying key customer segments, partnerships, value proposition as well as cost and revenue models, we were able to identify that this is opportunity can earn $1M in revenue within three years.

Look and Feel

This moodboard depicts the look, feel and emotion we think would be advantageous for Opus Mach to convey. Opus Mach is serving a society of makers who are innovative, iterative, they manufacture in the US, they are hi-tech, metallic, timeless, and most importantly - a part of history. Throughout American history, there have been remarkable inventions which have catapulted mankind, this aspirational message can be a cornerstone of Opus Mach’s brand. With Opus Mach’s location near GM, Ford, and Caterpillar, it can be a part of iterative manufacturing history in the making.

Printing Application

We identified four focuses for the printer solution: talent, suppliers, funds, and time. Opus Mach will need to assemble an internal research and development team to produce this printer. Funds and time will need to be dedicated to producing the machine. We estimate it will take $130,000 in research and development spend over 6 months to produce a proof of concept printer. Thereafter Opus Mach should iterate upon this design for a further 12 months. Through this time they will need an internal dedicated space for the employees and printer to conduct their research activities.

iPad 3D Printing Software Application for Robotic Printer

3-Year Timeline of Printer, Marketing, and Service Plans

For the service, we identified two segments: hire talent and implement scalable processes. First, Opus Mach needs to invest in the business development team, such as front-line sales representatives to scale to more customers, and a technical marketer to produce white papers and case studies. Opus Mach should also hire a front-end developer and marketing designer for some low-touch service solutions. Secondly, the company needs to implement scalable processes to ensure consistency of service. Starting with creating a sales playbook for IFF customers, onboarding a lead generation platform and creating an estimation cost model.

resultS

Learnings

If a robotic arm is used, it will need the precision to control each axis of motion in very short distances. This problem has been solved in high-end robotic arms, and the capability for a 6-axis robotic arm printer exists today. Instead of a robotic arm, another option would be to use linear actuators to move the extruding head of the printer. Linear actuators would make it easier to achieve the necessary precision, and could be a simpler overall design, making it a more robust engineering solution.

Our prototype shows that creating a robotic IFF machine is possible at a low cost. With an investment of $130,000, Opus Mach can achieve projected revenue of $1M and a profit of $240,000 by the third year. We have also learned that often start-up companies can gain recognition simply for researching and publicizing 3D printing technologies. This can pique the interest of larger companies like Ford and GE who are doing their own internal research, in turn promoting partnerships. Thus it would be worthwhile to create an IFF machine and publicize the research findings.

Credits

My teammates for this project were: Khanya Morolo (MIIPS), Daniel Clymer (additive manufacturing PhD), and Kartikay Sahay (MBA).